We survived the Burns Night, but our test layout didn't. (It was after all on the dinner table, and I didn't think it was quite up to hauling the haggis around the table!). I did manage to catch a few quick camera shots, before it all disappeared.

|

| Tri-ang R257 on straight section showing catenary |

The first pic shows the train on a straight. You can see how the catenary (overhead wire) sits nicely over the middle of the pantographs. The trouble starts when you drive your train around the bend.

|

diagram showing how straight catenary would run on

curved track |

Here is a diagram drawn using

XtrakCad which shows how a line drawn from centre line at one end of a curve to the centre line at the other end (the black line) actually veers off to the inside of the curve.

The pantographs won’t be able to reach across to this line and so won't collect any power. One alternative would be to split the curve into two – see the red lines. But even this line gets close to the edge line of the pantograph. (This would be the equivalent of the Marklin recommendation for a post every 22.5°).

|

| Tri-ang R257 on curved track showing catenary | |

The second pic shows the train on a curve. You can see how close the wire is to the edge of the pantograph (where I have added a small yellow arrow). What happens in practice is, unless you get it right, the pantograph slips off the wire. As it is sprung, it extends to its full height, and often continues to pick up power by scrapping along the side of the wire – until CRASH – it hits a post.

As you can see from the video of a couple of posts ago we did manage to get it right. First I had to straighten the individual strands of wire I had bent as a kid. One trick I picked up on the internet was to roll the wire – this shows where the bends actually are. It's quite a painstaking job to bend them back. Our test circuit was built using Tri-ang R483, first radius curves, with three straight sections (R480/R481) on either side of the oval. Without getting every “straight” section of wire really straight, the wire didn't quite meet in the middle. In the end I was able to ease some sections of the wire apart inside the connecting clips. This isn't ideal of course – but it worked!

|

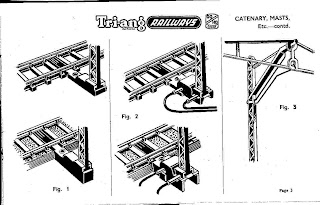

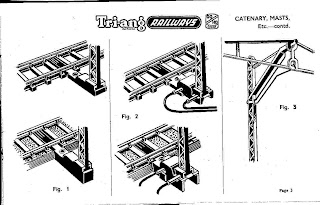

| Tri-ang catenary mast (R419) |

One other problem I had was with the mast clips – the little pieces of nylon which hang down from the top of the post. Here is a picture of one of the problem mast clips - if you look carefully you can see the wire is sitting behind the clip. The idea is that you push the wire up into the clip and the nylon springs closed around it, leaving the bottom edge free to touch the pantographs. But several of my old masts - like this one - had clips which just pushed the wire back out and wouldn't grip it. If anyone has any ideas how this might be solved I'd love to hear them.

We now have to work out just how to link in a Tri-ang overhead powered track section can fit into our main layout. We'll let you know if we solve that one!

And in the meantime, the words of Rabbie Burns’ Address to a Haggis are still ringing in my ears – “great Chieftain of the pudding race” – the proof of our pudding was watching the R257 zip around the track using overhead power with head lights blazing!